What is PWM Motor Control? – A Complete Guide for Beginners and Enthusiasts

Have you ever wondered how motor speed is controlled so precisely in electric vehicles, robotics, or even hydrogen generators? The answer lies in a powerful, elegant technique called PWM motor control – short for Pulse Width Modulation.

In this article, we’ll break down how PWM works, why it’s essential in DC motor control, and how you can choose the right controller for your application – whether you’re building an EV, an industrial system, or using PWM for HHO (hydrogen) systems.

🔧 What is PWM? (Pulse Width Modulation)

PWM is a method of delivering power by switching the voltage on and off very quickly, usually thousands of times per second. Instead of adjusting voltage levels (which is inefficient), PWM varies the duration of the ON vs OFF time in each cycle.

This is known as the duty cycle.

- A 100% duty cycle means the signal is always ON → full power

- A 50% duty cycle means it’s ON half the time → half power

- A 10% duty cycle means it’s barely ON → very low power

These pulses are so fast that the motor doesn’t “see” the individual on/off cycles. Instead, it responds as if it were receiving a steady, average voltage — which allows us to precisely control its speed and torque.

🌀 Why Use PWM for Motor Control?

PWM motor control is extremely efficient and widely used for brushed DC motors. Here’s why:

✅ Efficient: Less heat, less energy waste

✅ Precise: Fine-tuned speed control without jerky movement

✅ Flexible: Works across many voltages and motor types

✅ Safe: Allows for controlled ramp-up, braking, and direction changes

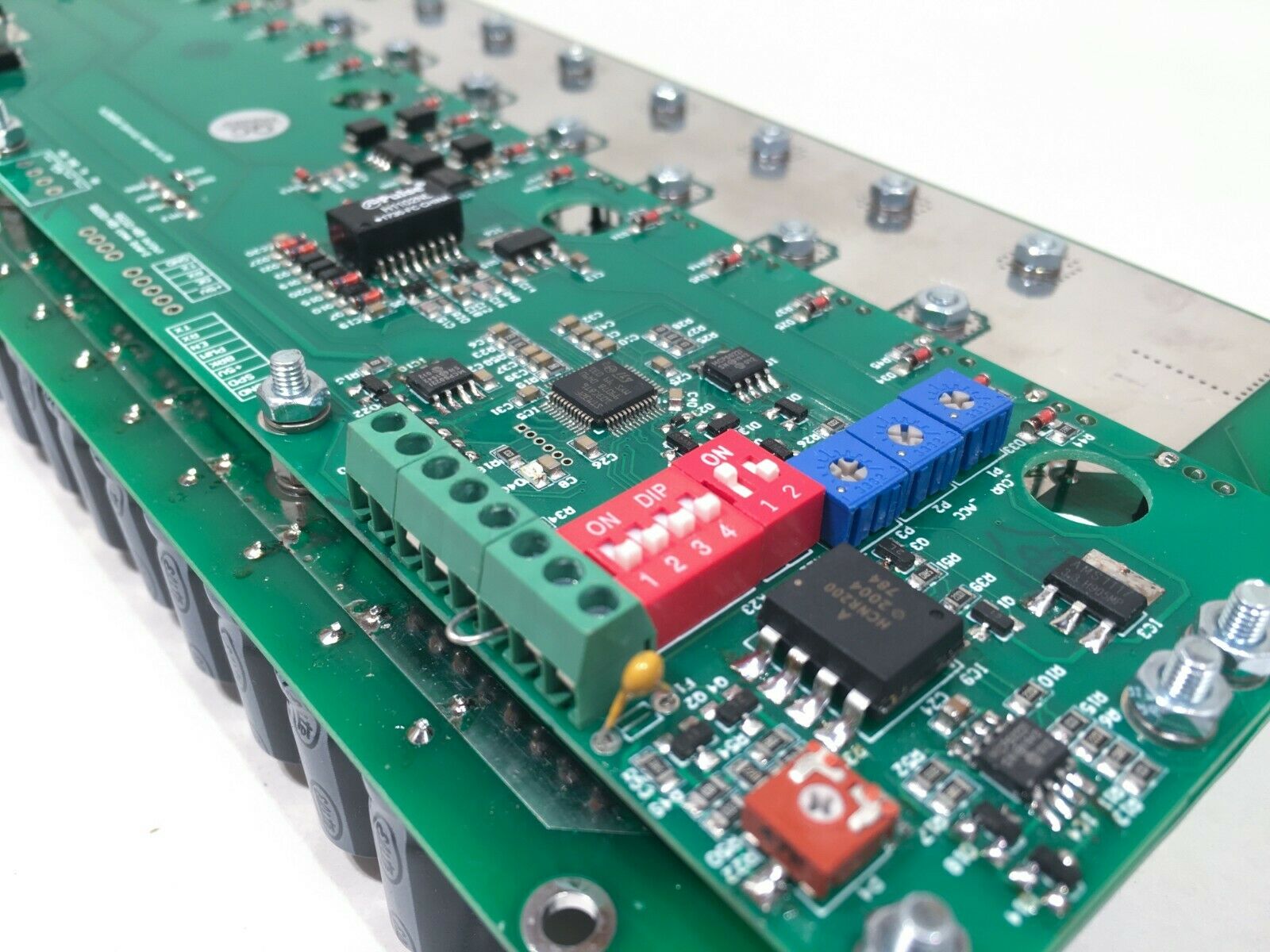

This is why we use PWM control in our Crocodile DC motor speed controllers, like the:

- Crocodile HL50100 – 50V DC Motor Speed Controller 200A

- Crocodile HL200200 – 100V DC Motor Speed Controller 500A

- Crocodile Mini PWM for HHO systems – 0–100A adjustable output

These devices all implement high-frequency PWM control (typically at 18kHz) using a 32-bit Cortex processor, ensuring ultra-smooth motor operation and energy-efficient control.

⚙️ How PWM Controls Motor Speed in Practice

Let’s say you have a 48V DC motor and you want to run it at half speed.

- If you apply 48V continuously (100% duty cycle), it runs at full speed.

- But with a 50% duty cycle, the motor only receives an average of 24V.

- The PWM controller switches the full 48V on and off rapidly, and the motor reacts to the average.

This method also enables regenerative braking, soft starts, and direction control – all features supported in our Crocodile motor controllers.

⚡ What Makes a Good PWM Motor Controller?

Here are some key specs to look for (which are present in our controllers):

✅ Wide input voltage support – e.g. 16–200V DC

✅ High output current – up to 300A peak

✅ Multiple input modes: potentiometer, hall sensor, joystick, PWM signal, RC signal

✅ Serial control (TX/RX) for advanced parameter tuning

✅ Regenerative braking

✅ 2 or 4-quadrant operation

✅ Overheat and current limit protection

🌊 PWM for HHO Systems – How It Helps

Hydrogen generators (HHO systems) benefit from adjustable current PWM controllers, like our HHO PWM Controller:

🟢 Adjust current from 0 to 100A smoothly

🟢 Maintain safe operating temperature of electrolyte

🟢 Reduce power waste and increase hydrogen production efficiency

PWM ensures precise electrolysis control – too much current = overheating; too little = low gas output. Our PWM units give you the sweet spot every time.

✅ Real-World Applications of PWM Motor Controllers

Our Crocodile PWM motor controllers are already used in:

🔋 Electric vehicles and e-bikes

🛳️ Electric boats and marine systems

🤖 Industrial robots and CNC machines

🏭 Forklifts and factory automation

🔧 HHO (hydrogen) generator setups

🛠️ Hobby and DIY electronics

Whether you’re building an EV, tuning a robot, or controlling gas output in an HHO system, PWM is the heart of it all — and we’re here to help you get it right.

🛍️ Explore Our PWM Motor Controllers

We offer a wide range of high-efficiency PWM motor controllers for all voltage ranges and applications:

Crocodile HL50100 – 50V 200A → Compact and powerful for EVs and robotics

Crocodile FR200200 – 200V 300A → Heavy-duty for high-voltage platforms

HHO PWM Controller → Specialized unit for hydrogen generation with fine current control

All models include overcurrent protection, regenerative braking, serial interface, and high-frequency PWM output.

🧠 Conclusion: PWM = Smart, Efficient Control

PWM is the most efficient way to control DC motor speed, whether you’re driving a 10kW electric motor or adjusting current to your HHO cell.

Understanding how PWM works gives you an edge when selecting the right controller. And if you’re looking for powerful, reliable, and configurable motor speed controllers — our Crocodile PWM series is ready to drive your next innovation.

Need help choosing a controller?

📩 Contact us for expert advice, or check out our Product Guide – How to Choose the Right Controller for a detailed breakdown.1HL

- There are one-way controllers.

- Reversible controllers.

- Potentially dual motor output controllers.

Power Supply Voltage:

The second critical criterion is the power supply voltage that will be used to operate the motor controller.

- The motor controller’s maximum supply voltage must always be higher than the supply voltage.

- If the system is high-current and has longer power supply cables, the motor controller’s maximum voltage should be 15-20% higher. This accounts for potential voltage fluctuations during startup.

Maximum Output Current & Continuous Load Capacity:

The third key factor is the motor controller’s maximum output current and its continuous load capacity.

- Generally, it is not a problem if the controller’s output current is lower than the motor’s current, as all of our circuits feature overcurrent protection.

- However, for full motor utilization, it is recommended to use a controller with a higher current rating, especially because motors often require higher output current during startup and acceleration.

Leave a comment

Your email address will not be published. Required fields are marked *